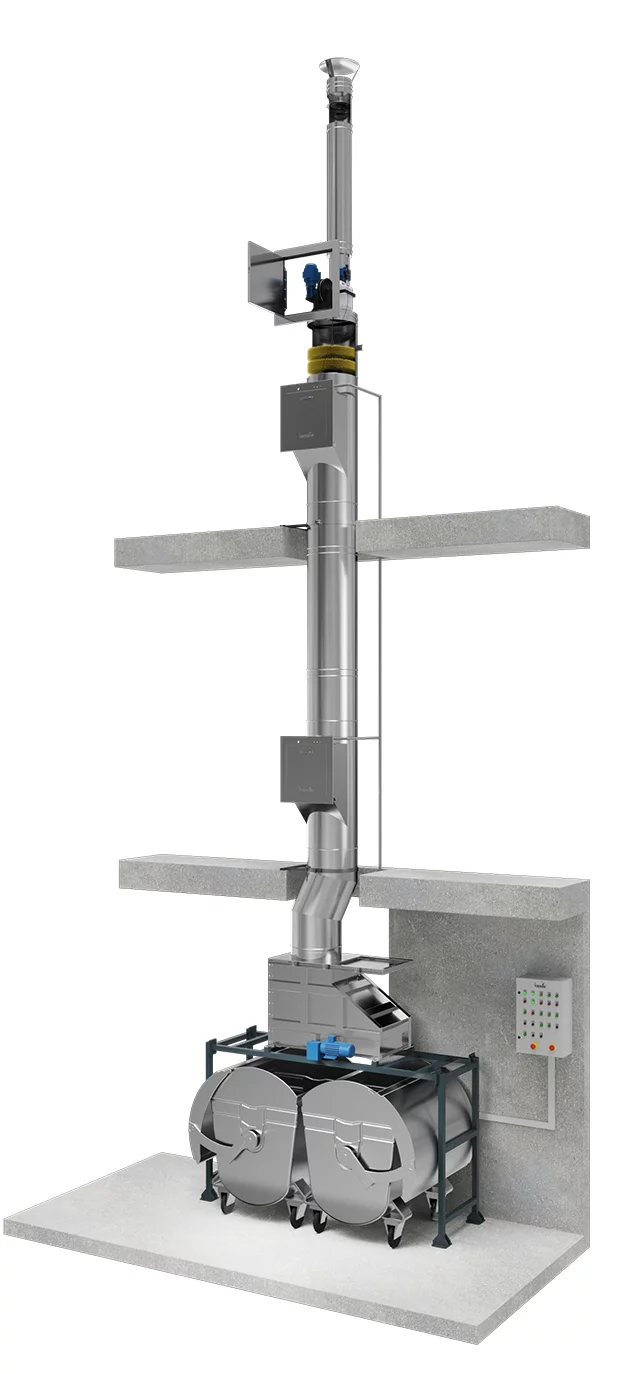

Recycling chute

Kapella's Recycling Chute Systems are the solution for forward-thinking buildings committed to a greener future. While sharing fundamental features with garbage and trash chute systems, they stand out with the inclusion of sorter units. These units are specially designed to separate various types of waste within a single chute shaft. Their user-friendly operation not only streamlines recyclable waste collection but also significantly reduces waste collection costs by eliminating the need for separate chute systems for each waste type.

With Kapella's Recycling Chute Systems, you can optimize your construction's space utilization, replacing multiple chute shafts with a single, versatile system. This simplifies the user experience, as individuals can select the waste type they're disposing of by pressing the corresponding button on the door panel. The system efficiently directs the waste to the designated container, ensuring proper separation and disposal. Join us in creating a more environmentally conscious and user-friendly recycling solution for your building.

You can see the system parts with their descriptions below.

Related Recycling Chute Parts

-

Recycling Bi-Sorter Unit

At Kapella, we’re at the forefront of innovative waste management solutions, and our Recycling Bi-Sorter Unit is a testament to our commitment to sustainable and efficient waste separation within trash or garbage chute systems. This electro-mechanic motorized sorter system is engineered to precisely distribute materials from one chute into designated containers, offering a streamlined approach to waste segregation.

The key feature of the Bi-Sorter Unit is its ability to segregate two different types of waste materials efficiently. Designed for integration into trash or garbage chute systems, this unit simplifies the separation of waste, ensuring that each type is collected in its designated container.

The operation of the Recycling Bi-Sorter Unit is straightforward and user-friendly. Building occupants select the waste type from the chute hopper door panel, aligning with what they intend to discard into the chute system. Once the waste type is chosen, the system smoothly rotates to the designated bin, facilitating the separation and collection of the wastes in separate containers.

Kapella’s Recycling Bi-Sorter Unit is a game-changer in waste management, providing a technologically advanced solution to enhance recycling and waste separation. By simplifying the process and improving efficiency, this innovative system plays a crucial role in promoting sustainability and eco-friendliness.

-

Recycling Multi-Sorter Unit

Kapella’s commitment to innovative waste management extends to our Recycling Multi-Sorter Unit, a cutting-edge solution for efficient waste separation within a trash or garbage chute system. Engineered for precision and operated by a powerful engine, this unit stands as a technological marvel designed to simplify waste segregation.

The heart of this system lies in its 360° rotating chute separator, which repositions itself as needed, aligning with predefined waste types and designated trolleys. This intelligent unit’s primary function is to separate various waste types deposited into the chute system, ensuring that recyclables and disposables are collected separately in different bins.

The operation of the Recycling Multi-Sorter Unit is straightforward. Building occupants select the waste type from the chute hopper door panel based on what they intend to throw into the chute system. Once the waste type is chosen, the system swiftly and accurately rotates to the corresponding bin, where it collects the waste separately, ensuring efficient waste separation.

Kapella’s Recycling Multi-Sorter Unit is a game-changer in waste management, offering a streamlined and technologically advanced solution for enhancing recycling and waste disposal efficiency. This innovative system not only simplifies waste separation but also contributes to a more sustainable and eco-friendly environment. Choose Kapella for an unmatched waste management experience that combines technology, precision, and sustainability.

- 300 kg Loading Capacity

- Epicyclical Gear

- 360 Degree Adjustable Control

- Special angle positioning for washing repositions from 0 degrees when the system is restarted

- Simple Configuration from Control Panel

- Sorts for different numbers of containers

-

Recycling Smart Control Panel

Kapella’s commitment to waste management technology extends to every aspect of our systems, and the Recycling Smart Control Panel is a testament to our dedication to precision, efficiency, and environmental responsibility. Strategically situated in the garbage collection room, this intuitive control panel plays a pivotal role in managing various chute accessories, including Sorter Units, automatic sanitizing systems, exhaust fans, brushing units, and interlocking doors.

The Recycling Smart Control Panel is designed with functionality and ease of use in mind. Its operation is facilitated through a user-friendly touchscreen panel, providing building managers and staff with an intuitive interface for controlling and configuring chute accessories. These panels are driven by a Programmable Logic Controller (PLC) unit, complemented by sophisticated software that optimizes performance, ensuring maximum efficiency and ease of operation.

While the primary application for these control panels is with Sorter Units in Recycling Chutes, their versatility extends to any type of chute system, offering adaptability and convenience. This adaptability allows you to tailor your waste management system to your specific needs, optimizing its functionality.

One of the key safety features of the Recycling Smart Control Panel is its integration with fire and smoke alarm systems. In the event of a fire, the control panel seamlessly interconnects with the building’s safety systems to initiate an automatic chute lockdown. This critical safety measure prevents the potential spread of fire or smoke through the chute system, contributing to the overall safety and well-being of building occupants.

Embrace the future of waste management with Kapella’s Recycling Smart Control Panel, a technological marvel that combines precision engineering with user-friendly operation. Take control of your waste management system with confidence and optimize its performance while enhancing safety standards. Choose Kapella and unlock the power of smart, efficient, and eco-conscious waste management.

-

Recycling Tri-Sorter Unit

Our Recycling Tri-Sorter Unit exemplifies our unwavering commitment to efficient and eco-friendly waste separation within trash or garbage chute systems. This electro-mechanic motorized sorter system is engineered to facilitate the precise distribution of materials from a single chute into designated containers, taking waste segregation to the next level.

A standout feature of the Tri-Sorter Unit is its remarkable capability to segregate three different types of waste materials efficiently. When integrated into trash or garbage chute systems, this unit streamlines waste separation, ensuring that each type is collected in its designated container. This not only simplifies waste disposal for building occupants but also contributes to responsible waste management practices.

Operating the Recycling Tri-Sorter Unit is user-friendly and intuitive. Building occupants select the waste type from the chute hopper door panel, aligning with the type of waste they intend to discard into the chute system. Once the waste type is chosen, the system elegantly rotates to the designated bin, enabling the effective separation and collection of the wastes in separate containers.

One of the remarkable benefits of the Tri-Sorter Unit is its space-saving design. By facilitating the segregation of three waste types within a single chute system, it eliminates the need for multiple chute systems for each waste type, optimizing space utilization and waste management efficiency.

Kapella’s Recycling Tri-Sorter Unit is a revolutionary addition to any waste management solution, offering advanced technology, precision, and environmental responsibility. Embrace this innovation for an enhanced waste segregation experience that promotes sustainability and eco-conscious practices, all while optimizing space usage.