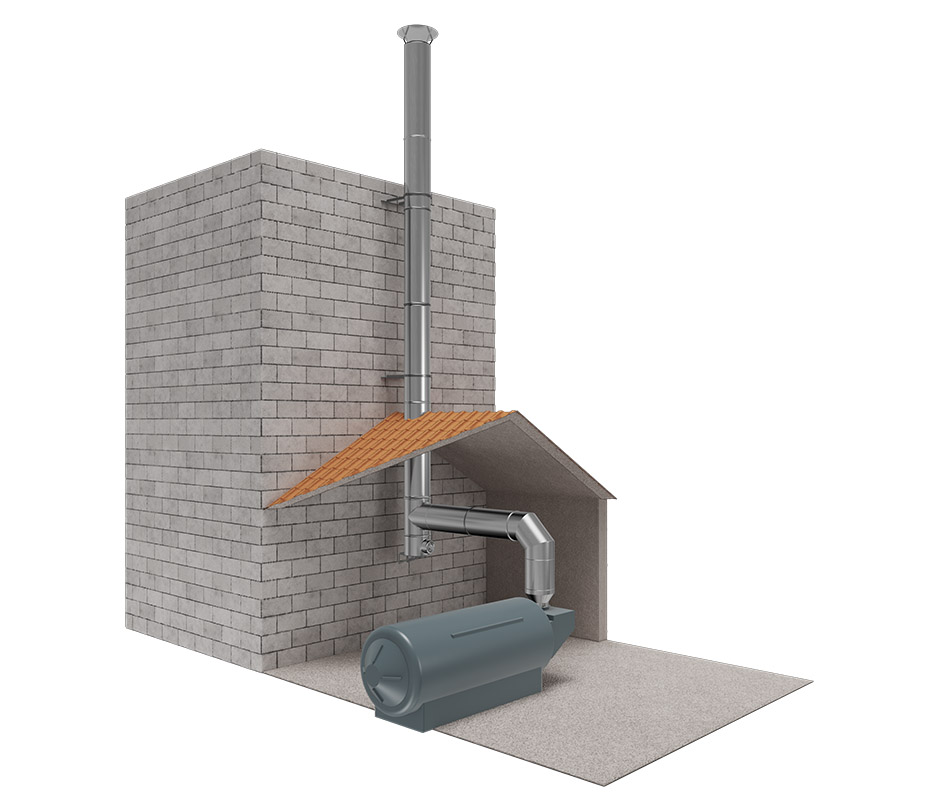

Double Wall Chimneys

Kapella double wall chimney systems are designed for exterior appliances.

AISI 316L stainless steel high quality inner liner is constructed in the range of 0,50 mm to 300 mm thickness.

30 mm thick 80kg/m3 or 50mm rock wool isolation.

AISI 316L stainless steel high quality outer liner is constructed in the range of 0,50 mm to 300 mm thickness.

The the thickness of the production of inner liner ranges from 100mm to 1200mm.